Reza Hajiha Senior / Electrical Engineer /Sharif University of Technology

Introduction

Safety is critically important to engineering personnel who work around powered hardware, especially if they work under considerable time pressures. Safety is not something to be taken lightly. Life safety systems are those designed to protect life and property. Such systems include emergency lighting, fire alarms, smoke exhaust and ventilating fans, and site security.

Facility Safety Equipment

Personnel safety is the responsibility of the facility manager. Proper life safety procedures and equipment must be installed. Safety-related hardware includes the following:

• Emergency power off (EPO) button. EPO pushbuttons are required by safety code for various types of facilities, including data processing (DP) centers. One must be located at each principal exit from the room. Other EPO buttons may be located near operator workstations. The EPO system, intended only for emergencies, disconnects all power to the room, except for lighting.

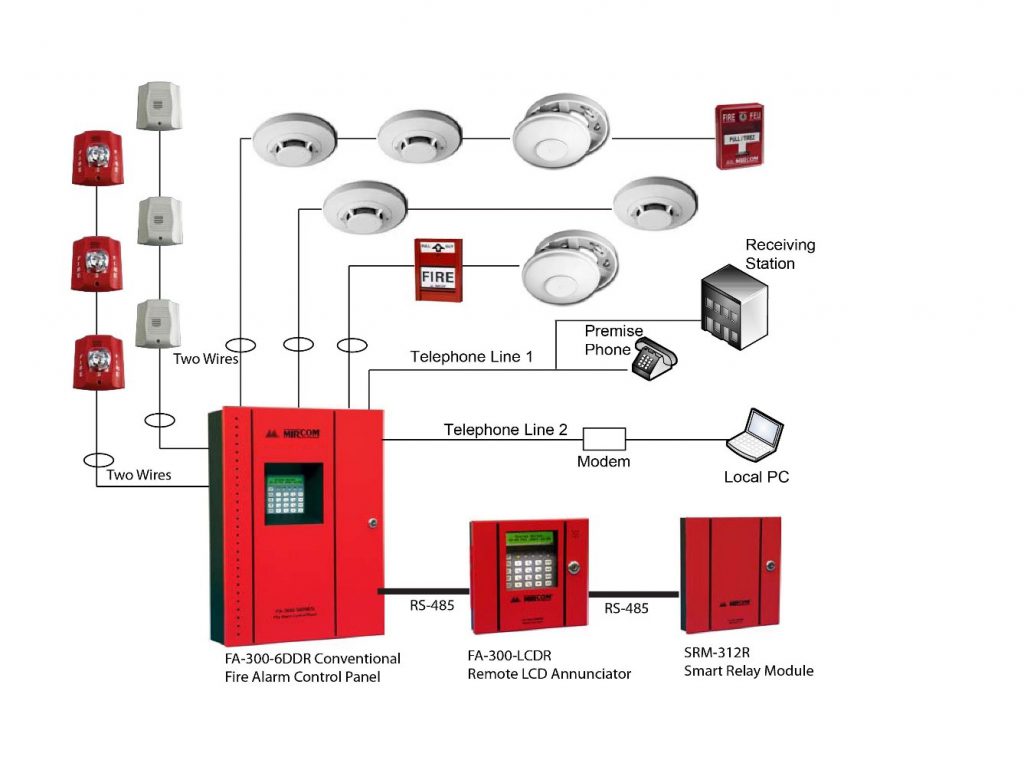

• Smoke detector. Two basic types of smoke detectors commonly are available. The first compares the transmission of light through air in the room with light through a sealed optical path into which smoke cannot penetrate. Smoke causes a differential or backscattering effect that, when detected, triggers an alarm after a preset threshold has been exceeded. The second type of smoke detector senses the ionization of combustion products rather than visible smoke. A mildly radioactive source, usually nickel, ionizes the air passing through a screened chamber. A charged probe captures ions and detects the small current that is proportional to the rate of capture. When combustion products or material other than air molecules enter the probe area, the rate of ion production changes abruptly, generating a signal that triggers the alarm.

• Flame detector. The flame sensor responds not to heated surfaces or objects, but to infrared when it flickers with the unique characteristics of a fire. Such detectors, for example, will respond to a lighted match, but not to a cigarette. The ultraviolet light from a flame also is used to distinguish between hot, glowing objects and open flame.

• Halon. The Halon fire-extinguishing agent is a low-toxicity, compressed gas that is contained in pressurized vessels. Discharge nozzles in data processing rooms and other types of equipment rooms are arranged to dispense the entire contents of a central container or of multiple smaller containers of Halon when actuated by a command from the fire control system. The discharge is sufficient to extinguish flame and stop combustion of most flammable substances. Halon is one of the more common fire-extinguishing agents used for DP applications. Halon systems usually are not practical, however, in large, open-space facilities.

• Water sprinkler. Although water is an effective agent against a fire, activation of a sprinkler system will often cause damage to the equipment it is meant to protect. Interlock systems must drop all power (except for emergency lighting) before the water system is discharged. Most water systems use a two-stage alarm. Two or more fire sensors, often of different design, must signal an alarm condition before water is discharged into the protected area. Where sprinklers are used, floor drains and EPO controls must be provided.

• Fire damper. Dampers are used to block ventilating passages in strategic parts of the system when a fire is detected. This prevents fire from spreading through the passages and keeps fresh air from fanning the flames. A fire damper system, combined with the shutdown of cooling and ventilating air, enables Halon to be retained in the protected space until the fire is extinguished.

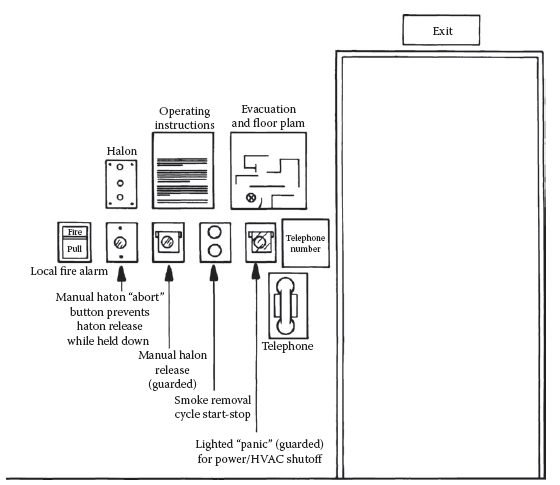

Many life safety system functions can be automated. The decision of what to automate and what to operate manually requires considerable thought. If the life safety control panels are accessible to a large number of site employees, most functions should be automatic. Alarm-silencing controls should be maintained under lock and key. A mimic board can be used to readily identify problem areas. Schematic 1.1 illustrates a well-organized life safety control system. Note that fire, HVAC (heating, ventilation, and air-conditioning), security, and EPO controls all are readily accessible. Note also that operating instructions are posted for life safety equipment, and an evacuation route is shown. Important telephone numbers are posted, and a direct-line telephone (not via the building switchboard) is provided. All equipment is located adjacent to a lighted emergency exit door.

machine parameters, water or Halon pressure, emergency battery-supply status, and other elements of the system that could compromise the ability of life safety equipment to carry out its functions. Basic guidelines for life safety systems include the following:

• Carefully analyze the primary threats to life and property within the facility. Develop contingency plans to meet each threat.

• Prepare a life safety manual, and distribute it to all employees at the facility. Require them to read it.

• Conduct drills for employees at random times without notice. Require acceptable performance from employees.

• Prepare simple, step-by-step instructions on what to do in an emergency. Post the instructions in a conspicuous place.

• Assign after-hours responsibility for emergency situations. Prepare a list of supervisors that operators should contact if problems arise. Post the list with phone numbers. Keep the list accurate and up-to-date. Always provide the names of three individuals who can be contacted in an emergency.

• Work with a life safety consultant to develop a coordinated control and monitoring system for the facility. Such hardware will be expensive, but it must be provided. The facility may be able to secure a reduction in insurance rates if comprehensive safety efforts can be demonstrated.

• Interface the life safety system with automatic data-logging equipment so that documentation can be assembled on any event.

• Insist upon complete, up-to-date schematic diagrams for all hardware at the facility. Insist that the diagrams include any changes made during installation or subsequent modification.

• Provide sufficient emergency lighting.

• Provide easy-access emergency exits.

The importance of providing standby power for sensitive loads at commercial and industrial facilities has been outlined previously. It is equally important to provide standby power for life safety systems.

A lack of ac power must not render the life safety system inoperative. Sensors and alarm control units should include their own backup battery supplies. In a properly designed system, all life safety equipment will be fully operational despite the loss of all ac power to the facility, including backup power for sensitive loads.

Place cables linking the life safety control system with remote sensors and actuators in separate conduit containing only life safety conductors. Study the National Electrical Code and all applicable local and federal codes relating to safety. Follow them to the letter.

Electric Shock

It takes surprisingly little current to injure a person. Studies at Underwriters Laboratories (UL) show that the electrical resistance of the human body varies with the amount of moisture on the skin, the muscular structure of the body, and the applied voltage. The typical hand-to-hand resistance ranges from 500 W to 600 kW , depending on the conditions. Higher voltages have the capability to break down the outer layers of the skin, which can reduce the overall resistance value. UL uses the lower value, 500W , as the standard resistance between major extremities, such as from the hand to the foot. This value generally is considered the minimum that would be encountered. In fact, it may not be unusual because wet conditions or a cut or other break in the skin significantly reduces human body resistance.

References

1. Federal Information Processing Standards Publication No. 94, Guideline on Electrical Power for ADP Installations, U.S. Department of Commerce, National Bureau of Standards, Washington, DC.2. Practical Guide to Ground Fault Protection, PRIMEDIA Intertec, Overland Park, KS.3. National Electrical Code, NFPA no. 70.4. Rudman, R., “Disaster Planning and Recovery,” in The Electronics Handbook, 2nd ed., J. C. Whitaker (Ed.), CRC Press, Boca Raton, FLSafety and protection systems

Download Pdf verrsion:

رضا حاجیها- کارشناس ارشد برق – دانشگاه صنعتی شریف