Reza Hajiha/Senior Electrical Engineer/Sharif University of Technology

Abstract

The subject of electrical hazards analysis has been recognized by a small segment of the electrical industry for many years. The petrochemical industry and many government institutions have performed research on this subject for over twenty years. For the most part however, the electrical industry, at least at the user level, has largely ignored the subject, essentially reacting to catastrophic accidents, rather than proactively trying to predict and prevent them. Recent changes in consensus standards, along with a better general understanding of the seriousness of electrical hazards have resulted in a renewal of interest in the subject.

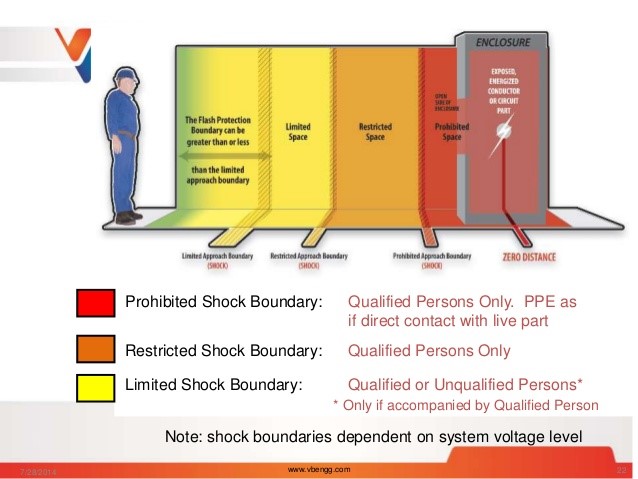

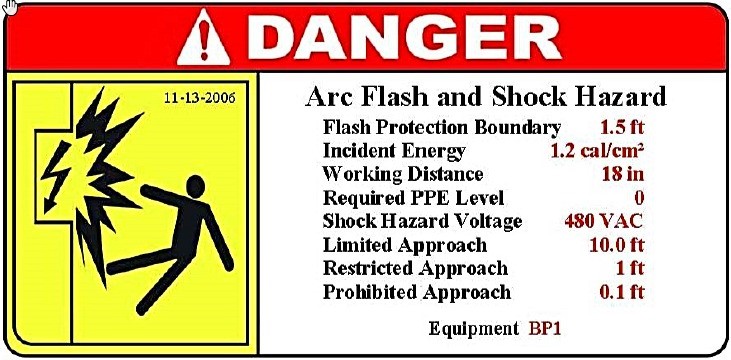

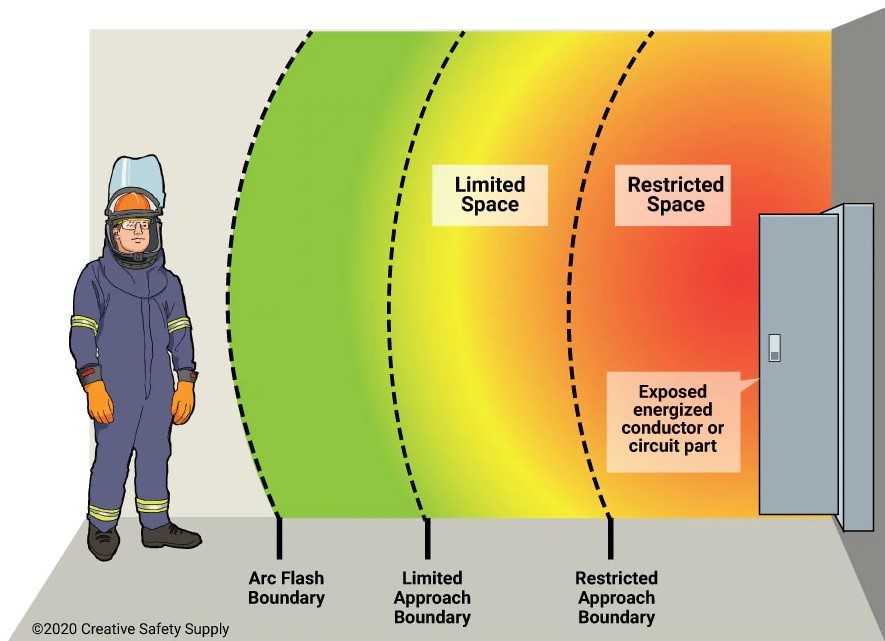

As the awareness of electrical hazards increase many are puzzled by phrases like; “Limited”, “Restricted”, and “Prohibited Approach Boundary”, and “Flash Protection Boundary”. Understanding these terms is important to understanding shock and arc-flash hazard protection.

NFPA 70E-2004, Standard for Electrical Safety in the Workplace requires that an electrical hazards analysis be performed prior to working on or near exposed energized electrical conductors and circuit part operating at 50-volts or more. This is especially critical if the circuits have not been placed in an electrically safe work condition.

This paper will address the requirements to perform the “Shock Hazard Analysis” and the “Flash Hazard Analysis”.

Required by NFPA 70E-2004, Section 110.8(B) (1), “Electrical Hazard Analysis” as well as the “Blast Hazard Analysis” and personal protective equipment requirements.

۱. INTRODUCTION

Below are the definitions of these terms as found in NFPA 70E-2004, Article 100: [1]

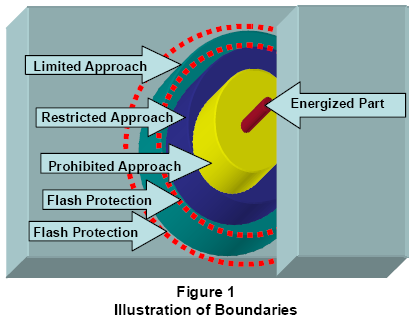

Limited Approach Boundary- “An approach limit at a distance from an exposed live part within which a shock hazard exists.” NOTE: Limited Approach Boundary may be more or Less than Flash Protection Boundary as illustrated in Figure 1.

Restricted Approach Boundary- “An approach limit at a distance from an exposed live part within which there is an increased risk of shock, due to electrical arc over combined with inadvertent movement, for personnel working in close proximity to the live part.

Prohibited Approach Boundary- “An approach limit at a distance from an exposed live part within which work is considered the same as making contact with the live part.”

Flash Protection Boundary- “An approach limit at a distance from exposed live parts within which a person could receive a second degree burn if an electrical arc flash were to occur.

The NFPA 70E-2004, “Standard for Electrical Safety in the Workplace”, addresses the requirements for conducting an “Electrical Hazard Analysis” with emphasis on the “Shock Hazard Analysis” and the “Flash Hazard Analysis”. NFPA 70E-2004 states that if circuits, operating at 50 volts or more, are not DE energized (placed in an electrically safe work condition) then other electrical safety-related work practices must be used.

These work practices must protect the employee from an arc flash, as well as inadvertent contact with live parts operating at 50 volts or more. Each analysis must be performed before an employee approaches exposed live parts, within the Limited Approach Boundary. NFPA 70E-2004, paragraph 130.2(B) FPN provides a reminder that the Flash Protection Boundary may be a greater distance from the exposed live parts than the Limited Approach Boundary, in some instances.

This paper will provide an overview of the principle types of electrical hazards analysis, along with a discussion of the relevant standards and regulations pertaining to the subject.

۲. Shock Hazard Analysis

Each year several hundred workers are injured or killed due to inadvertent contact with energized conductors.

Surprisingly, over half of those killed are not in traditional electrical fields (i.e. linemen, electricians, technicians, etc.), but are from related fields such as painters, laborers, and

drivers. [Detailed surveillance data and investigative reports of fatal incidents involving workers who contacted energized electrical conductors or equipment are derived from the

National Traumatic Occupational Fatalities (NTOF) surveillance system maintained by the National Institute for Occupational Safety and Health (NIOSH)]. NFPA 70E-2004.

Established a requirement for conducting the “Flash Hazard Analysis” to assist in reducing these injuries and fatalities.

This analysis will: determine the voltage that a person would be exposed to, establish the shock protection boundaries, and identify the personal protective equipment requirements.

Investigations into the causes of injuries and fatalities point to several contributing factors [2]:

-Contacting overhead power lines;

-Faulty insulation;

-Improper grounding;

-Loose connections;

-Defective parts;

Ground faults in equipment;

-Unguarded live parts;

-Failure to reenergize electrical equipment when it is

-being repaired or inspected;

-Intentional use of obviously defective and unsafe tools; or

-Use of tools or equipment too close to energized parts.

These factors form the basis for a shock hazard analysis. To appropriately assess the electrical shock hazard associated with any type of maintenance or repair work, it is necessary to evaluate the procedures or work practices that will be involved. These practices should be evaluated against both regulatory and consensus standards requirements as well as recognized good practice within the industry. These principles are summarized below.

· All equipment must be placed in a DE energized state prior to any maintenance or repair work. (limited exceptions exist). [3][4]

· The DE energized state must be verified by a qualified person prior to beginning any work. [3]

· The DE energized state must be maintained through the consistent use of locks and tags, and in some cases, grounding. [3][4][5]

· When energized work is performed, it must be performed in accordance with written procedures. [3][6]

NFPA 70E-2004 Standard Requirements [۱]

· The Shock Hazard Analysis must establish the:

۱. Limited Approach Boundary

۲. Restricted Approach Boundary

۳. Prohibited Approach Boundary

· This applies to all exposed live parts operating at 50 volts or more

· Only qualified persons are permitted within these boundaries NOTE: A qualified person shall be trained and knowledgeable of the construction

and operation of equipment or a specific work method, and be trained to recognize and avoid the electrical hazards that might be present with respect to that equipment or work method.

· Paragraph 110.8 (B)(3) states that unqualified person may not enter these boundaries unless the conductors and equipment have been placed in an electrically safe work condition. However, paragraph 130.2(D)(2) allows unqualified persons to enter the Limited Approach Boundary only, but a qualified person must advise them of the hazards and continuously escort the them while they are inside the boundary. NOTE: An employee, who is undergoing on-the-job training and who, in the course of such training, has demonstrated an ability to perform duties safely at his or her level of training and who is

under the direct supervision of a qualified person shall be considered to be a qualified person for the performance of those duties.

References

[۱] NFPA 70E-2004, Standard for Electrical Safety in the Workplace.

[۲] OSHA 29 CFR 1910, Electrical Standards, Federal Register.

[۳] OSHA 29 CFR 1910.331-.335, Electrical Safety- Related Work Practices.

[۴] OSHA 29 CFR 1910.147, Control of Hazardous Energy Source.

[۵] OSHA 29 CFR 1910.269, Electric Power Generation, Transmission, and Distribution.

[۶] OSHA Instruction STD 1-16.7, Directorate of Compliance Programs.