Electrical Engineering Applications and Sustainable Architecture In field of Building Constructions

Reza Hajiha /Senior Electrical Engineer /Sharif University of Technology

Sustainable architecture

Sustainable architecture is a general term that describes environmentally-conscious design techniques in the field of architecture. Sustainable architecture is framed by the larger discussion of sustainability and the pressing economic and political issues of our world. In the broad context, sustainable architecture seeks to minimize the negative environmental impact of buildings by enhancing efficiency and moderation in the use of materials, energy, and development space.

In residential and commercial buildings, most components of electrical installations are hidden from sight – only elements like lighting fixtures and receptacles are exposed, since their function requires it. The role of electrical systems in building interiors is much more evident in industrial settings, where there are no dropped ceilings or dry walls to hide conduit, junction boxes and other accessories.

Practically all building systems have at least one electrical component, even if the main energy input is not electricity. For example, space heating systems rely on motor-driven fans to distribute air, and gas-fired equipment in commercial kitchens uses electronic controls. Electricity is normally associated with lighting fixtures, power outlets and air conditioners, but its coverage is much broader!

Electricity is the fastest and cheapest energy transmission method known by modern society, but this also makes it dangerous. If a high-magnitude current is not interrupted quickly, it can easily start a fire.

Electrical Engineering Services

Electrical installations have a very important role in buildings, since they provide an energy source for many appliances and building systems. In modern society, electric current is the fastest and most efficient method to deliver energy. However, the power of electricity also makes it dangerous when not used property, and electrical systems must be safe and reliable.

Buildings use plenty of equipment and devices that run with electricity. There are many types of electrical installations, but they must all meet two common requirements:

Being able to deliver enough power for all the electrical devices connected, while keeping a stable voltage.

Operating safely without exposing occupants to electric shock, and without creating fire hazards.

The NFPA 70 National Electrical Code (NEC) is one of the most widely used references for electrical design, not only in the USA but also internationally. The NEC was developed by the National Fire Protection Association, and the first edition was published more than a century ago in 1897. The code is reviewed and updated every three years to keep up with the latest technologies, and the most recent edition was published in 2020. Cities, states and even entire countries have created their local electrical codes based on the NEC.

Delivering enough power and operating safely are basic requirements for all electrical installations. However, electrical engineers also recommend the use of energy efficiency measures. While these measures may increase the initial cost of your electrical systems, every dollar invested is recovered several times during the service life of your building. If the local power grid is dependent on fossil fuels, energy efficiency will also reduce the carbon emissions produced by your building.

Generating electricity on site is now viable, and solar panels in particular can adapt to buildings of all sizes and occupancies. However, a safe and reliable electrical installation is important even when clean energy sources are used. Also, energy efficiency maximizes the value of every kilowatt-hour produced.

Sizing Your Electrical Installations Correctly

Many calculations involved in electrical design have the purpose of finding the optimal size of equipment and components:

When an installation is undersized, wiring and other components can overheat, causing an early failure and possibly electrical faults. Undersized wiring also causes voltage drop issues, which damage some devices.

On the other hand, an oversized electrical installation is more expensive than necessary. Unless you plan to add more electrical loads to the system in the future, there is no point in oversizing.

If you are willing to invest more in an electrical installation, energy efficiency measures and renewable generation systems are much better ways to use your budget. Oversizing is not recommended, unless you plan to connect more electrical load in the future.

Sizing an electrical installation is a design process that involves many steps. First of all, electrical engineers must know all the electrical loads that will be connected to the installation. These include lighting fixtures, home appliances, office appliances, air handlers, air conditioning units, pumps and IT equipment.

Electrical loads are then grouped by categories, and similar devices share electrical circuits. For example, installing individual wiring for every lighting fixture is too expensive, and for this reason fixtures are arranged in lighting circuits. If a circuit contains 20 lamps that consume 200 watts each, it must be capable of carrying 4000 watts (4 kilowatts) safely and reliably.

The total current carried by an electrical circuit determines the conductor size. In turn, the wiring diameters of a circuit determine the conduit or raceway where it will be installed. During the electrical design process, engineers calculate wiring and conduit sizes for all the expected loads in a building. These circuits that power electrical appliances and equipment are called branch circuits.

Individual branch circuits are connected to distribution boards, where each of them is protected by a circuit breaker. In turn, distribution boards are powered by larger feeder circuits, which connect to the main electrical service equipment.

Our electrical engineers use Building Information Modeling (BIM) and advanced design software to optimize the layout of all building systems, including electrical installations. By reducing the total length of wire and conduit used in your building, we can reduce the total cost of your electrical systems.

Importance of Having Adequate Electrical Protections

Electrical protections have a very important function in buildings: when an electrical fault occurs, they disconnect the affected circuits immediately. If an electrical circuit is left connected with an active fault, the consequences can include major component damage, fire, or electric shock.

Most electrical protection devices use thermal or magnetic mechanisms to disconnect faults, and many protection devices use both types.

Thermal protections use the heat released by the high electrical current that occurs during a fault. The heat expands a contact inside the protection device, opening the circuit and interrupting the fault current.

Magnetic protections respond to the magnetic fields caused by fault currents, opening the circuit in response. Since there is no heating involved, magnetic protections act faster than thermal protections.

Magnetic protections may seem like a better option because they are faster, but this is not the case – each protection mechanism is suited for different applications. Devices like electric motors and lamps with ballasts have a brief inrush current when they activate, and the magnetic protection must not trip with this current. Instead, the magnetic protection must be calibrated for much higher currents, such as those found in short circuits and ground faults.

There are cases where a high current lasts longer than normal, indicating a fault. For example, an inrush current is normal when a motor starts, but an operating current above the motor’s nameplate value indicates an overload. In this case, a thermal protection device heats up and trips with the overload current.

There are many types of protection devices, each designed for different applications. The following are some of the most common types found in residential and commercial buildings:

Miniature circuit breaker (MCB), also known as plug-in circuit breaker, which is normally used for loads below 100A.

Molded case circuit breaker (MCCB), which can be used for larger loads up to 2500A.

Ground-fault circuit interrupter (GFCI) and arc-fault circuit interrupter (AFCI), which are used to protect against ground faults and arc faults, respectively.

Motor circuit protector (MCP), a magnetic protection designed for motor-driven loads, as implied by its name.

Motor protection circuit breaker (MPCB), which is similar to an MCP, but including thermal protection as well.

Fuses, which are thermal-only devices that disconnect a circuit by melting. Fuses can only be used once, unlike circuit breakers, since they are destroyed during a fault.

Some appliances and equipment need more than one type of protection to achieve full safety. For example, power outlets in bathrooms are protected by a circuit breaker at the distribution board, but they also use an integrated GFCI.

Circuit breakers are arranged in distribution boards, which have special contacts and terminal blocks to simplify connections. Each distribution board must be specified with enough spaces for all the circuits that will be connected. Note that circuits with two live conductors use 2-pole breakers, while three-phase circuits use 3-pole breakers. These circuit breakers with more than one pole use several spaces in the distribution board.

Circuit breakers and other electrical protections are only reliable if they are suited for the application at hand. Using high-quality products is important, but their capacity can only be specified after a detailed electrical load calculation.

Sizing Feeder Circuits and Service Equipment

After sizing the branch circuits and distribution boards needed for a building, electrical engineers can design the larger feeder circuits that power these boards, and the service equipment that connects to the local power grid. Any renewable energy systems or backup generators used in the building will normally connect to the main service equipment.

Feeder circuits are similar to branch circuits, since they use conductors that run in conduit or raceway. However, feeders are characterized by larger wires, and they use large protection devices such as molded-case circuit breakers (MCCB). Feeder circuits connect to switchgear panels, which are larger versions of the distribution boards used in branch circuits. Electrical transformers are also required to step down the voltage in larger facilities, or installations that use multiple voltages.

Since the electrical components used in feeders and switchgear are the largest, they are also the most expensive. However, you can find the optimal sizes for these components by working with experienced electrical engineers. Professional design services also ensure that your installation meets local building codes and the NFPA 70 NEC.

Electrical installations must also meet requirements from the local power company, which depend on the voltage supply needed by the building. For example, small residential installations connect to single-phase low-voltage, while large commercial and industrial buildings normally use a three-phase high-voltage connection.

Emergency Power System Design

Building codes normally require an emergency power system, to ensure that key equipment can stay operational during an electric service interruption. This includes fire protection systems, since they must be capable of responding to fire 24/7, even during blackouts.

Diesel generators are the most common option to supply emergency power in buildings, but natural gas generators and battery arrays are emerging as viable alternatives. Emergency power systems are subject to stringent specifications and building code requirements, due to their critical function.

Importance of Energy Efficiency in Electrical Design

Many energy efficiency measures increase the initial cost of a building, but the long term benefit is much greater. For example, LED lighting has a higher price than older types of lighting, but it often achieves a payback period of less than three years. LEDs also last much longer than the lamps replace, and many of them can operate for more than a decade. In addition to saving electricity, LED lighting saves many lamp replacements over time.

Since energy efficiency measures reduce the power consumption of your building, it may be possible to size some electrical components smaller. This will reduce the initial cost of electrical installations, helping compensate for the extra cost of energy efficient equipment.

Every building is unique, and energy efficiency measures must be selected based on a careful analysis of each project. The same measure can achieve good results in one project and poor results in another.

Requirements for a Safe Electrical Installation

Electrical safety does not depend on a single device, and it must be engineered into all electrical components.

-Electrical equipment must be manufactured safely, and there are many industry associations and regulatory bodies that have assumed this responsibility in the USA. The National Electrical Manufacturers Association (NEMA) and Underwriters Laboratories (UL) are perhaps the best-known examples – equipment that does not meet NEMA and UL requirements if often rejected.

-Conductors and electrical protections must be suitable for the equipment they power. Even if your entire electrical system uses approved components, there may be faults due to conductors and protections of the wrong capacity – the insulation on an overloaded conductor melts, and oversized breakers do not clear low magnitude faults.

All electrical components carrying voltage must be isolated from the public. In residential and commercial settings, energized devices are close to persons of all ages and professional backgrounds. Electrical installations must be designed to prevent any type of accidental contact with live conductors.

-Requirements for electrical installations become less stringent in areas that are only accessed by trained personnel, such as mechanical and electrical rooms. Transformers and switchgear are dangerous for untrained personnel, even when the equipment meets all applicable codes and standards.

Energy Efficiency in Electrical Installations

A safe electrical installation is not necessarily efficient, but a professional design firm will normally propose measures that help reduce your power bills. Energy efficiency can actually make your installation safer, and LED lighting is a great example of this:

-LED lamps can be manufactured free from electrical components, while most other lamp types are prone to breaking – incandescent, halogen, fluorescent and HID.

-LED lamps also have a lower heat footprint, reducing their chance of starting a fire. In addition, most LED bulbs will not burn your hand if touched accidentally, except for those in high-power applications.

The electrical safety requirements in the NEC and equivalent codes are always mandatory, while the rules for energy efficiency change by location. For example, the NYC Energy Conservation Code establishes a minimum efficiency level for buildings, but this level is significantly below the top efficiency possible with modern technologies.

Sustainable energy

Energy efficiency over the entire life cycle of a building is the most important single goal of sustainable.

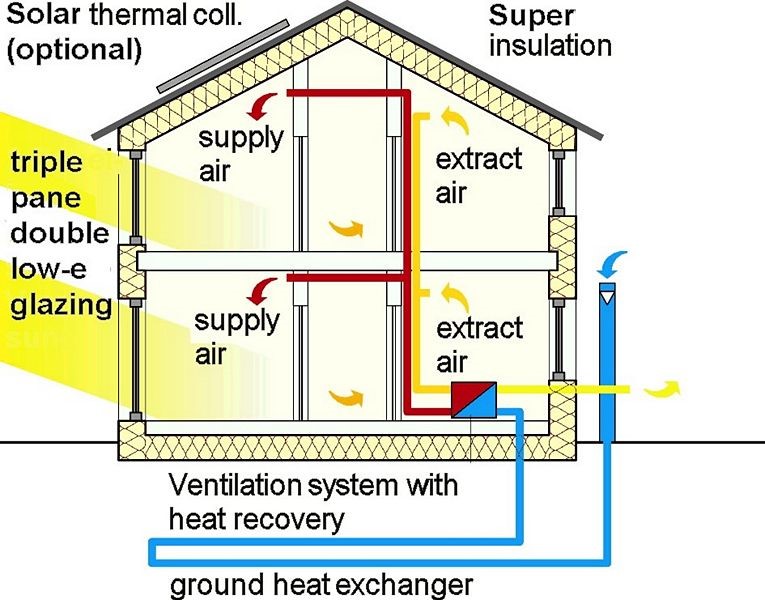

Heating, Ventilation and Cooling System Efficiency

The most important and cost effective element of an efficient heating, ventilating, and air conditioning (HVAC) system is a well insulated building. A more efficient building requires less heat generating or dissipating power, but may require more ventilation capacity to expel polluted indoor air.

Significant amounts of energy are flushed out of buildings in the water, air and compost streams.

Off the shelf, on-site energy recycling technologies can effectively recapture energy from waste hot water and stale air and transfer that energy into incoming fresh cold water or fresh air. Recapture Of energy for uses other than gardening from compost leaving buildings requires centralized anaerobic digesters.

Site and building orientation have a major effect on a building’s HVAC efficiency.

Convective heat transfer

Convective heat transfer can be beneficial or detrimental. Uncontrolled air infiltration from poor weatherization / weather-stripping / Draught-proofing can contribute up to 40% of heat loss during winter, however strategic placement of operable windows or

Vents can enhance convection, cross-ventilation, and summer cooling when the outside air is of a comfortable temperature and Relative humidity. Filtered energy recovery ventilation systems may be useful to eliminate undesirable humidity, dust, pollen, and microorganisms in unfiltered ventilation air.

Radiative heat transfer

The main source of heat transfer is radiant energy, and the primary source is the sun. Solar radiation occurs predominantly through the roof and windows (but also through walls). Thermal radiation moves from a warmer surface to a cooler one.

Roofs receive the majority of the solar radiation delivered to a house. A cool roof, or green in addition to a radiant barrier can help prevent your attic from becoming hotter than the peak summer outdoor air temperature.

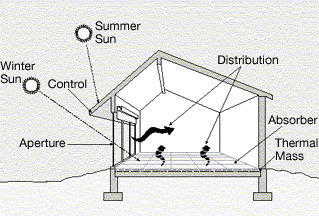

Direct solar gain

Direct gain attempts to control the amount of direct solar radiation reaching the living space. The cost effectiveness of these configurations is currently being investigated in great detail and is demonstrating promising results.

Angle of incident radiation

The amount of solar gain transmitted through glass is also affected by the angle of the incident solar radiation. Sunlight striking glass within 20 degrees of perpendicular is mostly transmitted through the glass, whereas sunlight at more than 35 degrees from perpendicular is mostly reflected Alternatively, passive solar computer software can determine the impact of sun path, and cooling-and-heating degree days on energy performance. Regional climatic conditions are often available from local weather services.

Operable shading and insulation devices

Although the sun is at the same altitude 6-weeks before and after the solstice, the heating and cooling requirements before and after the solstice are significantly different. Heat storage on the Earth’s surface causes “thermal lag.” Variable cloud cover influences solar gain potential. This means that latitude-specific fixed window overhangs, while important, are not a complete seasonal solar gain control solution.

Control mechanisms (such as manual-or-motorized interior insulated drapes, shutters, exterior roll-down shade screens, or retractable awnings) can compensate for differences caused by thermal lag or cloud cover, and help control daily / hourly solar gain requirement variations. Home automation systems that monitor temperature, sunlight, time of day, and room occupancy can precisely control motorized window-shading-and-insulation devices.

Exterior finishes

Materials and colors can be chosen to reflect or solar thermal energy. See “Cool Colors” by Lawrence Berkeley National Laboratory and Oak Ridge National Laboratory

Landscaping

Energy-efficient landscaping materials, including the use of trees, plants, hedges, or a trellis (agriculture), can be used to selectively create summer shading (particularly in the case of deciduous plants that give up their leaves in the winter), and also to create winter wind chill shelter. Xeriscaping is used to reduce or eliminate the need for energy-and-water-intensive irrigation.

Brief Summary of the Electrical Design Process

Many electrical design requirements are determined based on other other building systems, not directly from the owner’s requirements. Consider the following examples:

The capacity of boilers and air conditioning equipment is directly determined from the heating and cooling needs of the building. On the other hand, the corresponding electrical installation is determined by the load of motor-driven equipment such as fans and compressors.

A similar concept applies for lighting design: Fixtures are selected based area and illuminance requirements, while electrical systems depend on their power consumption.

Design engineers must analyze the power requirements of equipment in the building before specifying the electrical installation that will supply that power at the correct voltage. Keep in mind that designers may suggest energy efficiency measures to reduce total electrical load, and the following are some examples:

NEMA Premium Efficiency motors with speed controls (VFD) for equipment above 1 hp.

Brushless DC motors for fractional horsepower equipment.

LED lighting, as previously mentioned.

ENERGY STAR appliances.

Air conditioning equipment with smart compressors.

Efficient electrical equipment draws less current, reducing the capacity of the electrical system. Significant cost reductions are possible by optimizing the capacity of wiring, load centers, switchgear and transformers.

Reference Standards

-NFPA 70 -NEMA -NEC

دریافت متن مقاله با فرمت pdf: